Various small villages in Kutch are

hugely moored in forms on traditional art. Right from Rogan Art to Weaving, rare

art forms have passed down generation after generation. Ajrakh, an art deeply

rooted in ancient times, is one such practice. In fact, its origins can be

traced back to the Indus valley civilization.

Even though

the art seems to have emerged in Sindh, it has traveled down to Rajasthan and Gujarat over the centuries. Ajrakh has different meanings, one of which means

to ‘keep it today’. During the olden days the color blue was a dominating color

used and hence in Sindh Ajrakh was associated with Indigo.

Complex

geometric patterns were used to create starry constellations in Indigo, Madder

(a red dye or pigment obtained from the root of the Madder, or a synthetic dye

resembling it), Black and White across lengths of cloth. The motifs and shapes used

are a vestige of Islamic architecture’s intricate windows and trefoil arches. Ajrakh

is a time-honored emblem for the local communities of Kachchh. Communities like

the Rabaris, Maldharis, and Ahirs wear Ajrakh printed cloth as turbans, lungis,

or stoles. It was given as a gift for the Muslim festival of Eid, for

bridegrooms, and for special occasions.

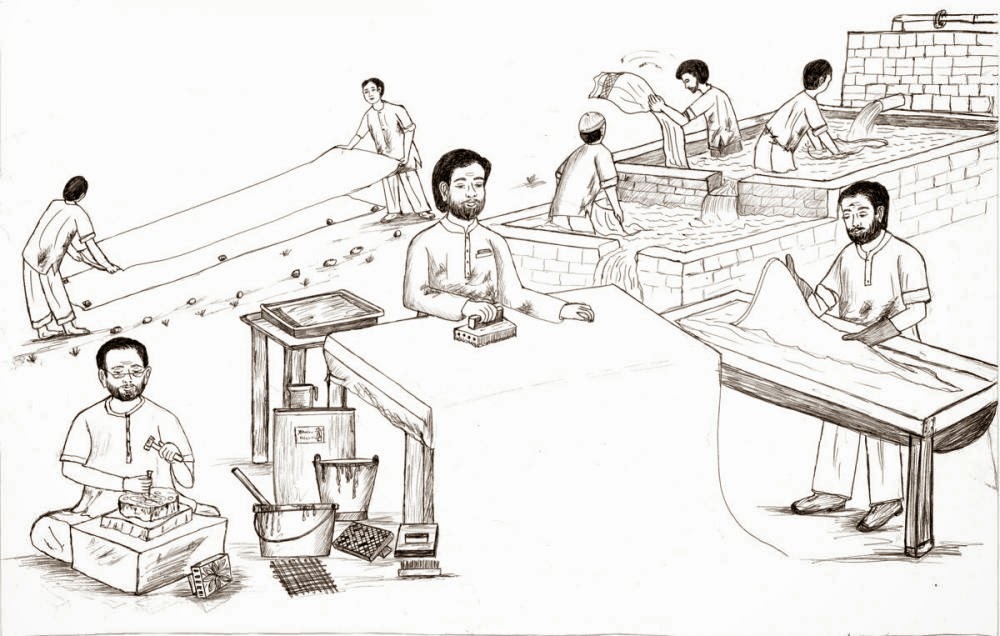

Preparing the cloth is a sixteen step process and takes days, which

involves washing, dyeing, printing and drying. A high level of skill and

concentration is required in order to keep the colors even. The fabric is first

soaked in a mixture of dung, oil and water to make it soft. Left for days to

dry, the fabric is re-soaked in more natural ingredients to bleach preparing it

for printing.

A wooden block craved with traditional designs is selected by an artisan,

on which the first bock is coated in lime and Acacia gum which acts as a resist

when pressed on the cloth at regular intervals. Selecting and coating the

blocks in dye, aligning and pressing carefully are critical parts of the

procedure.

Natural colors are used, some of which are pomegranate

seeds, gum, Harde powder, wood, flour of Kachika, flower of Dhavadi, alizarine

and locally cultivated Indigo. Jaggery and gram flour are used for Black

designs; alum and tamarind for Red. After each layer of print the cloth is

rinsed and sun-dried. On completion, the cloth is washed and dyed in natural

colors and finally laid out for drying in the sun.

Today the Khatri community appears to

be have monopolized the art in Gujarat. They have passed the teaching for nine

generations and Dr.

Ismail Mohammad Khatri is one of the few with the knowledge of the art and will

later pass it down to his sons as well.

No comments:

Post a Comment